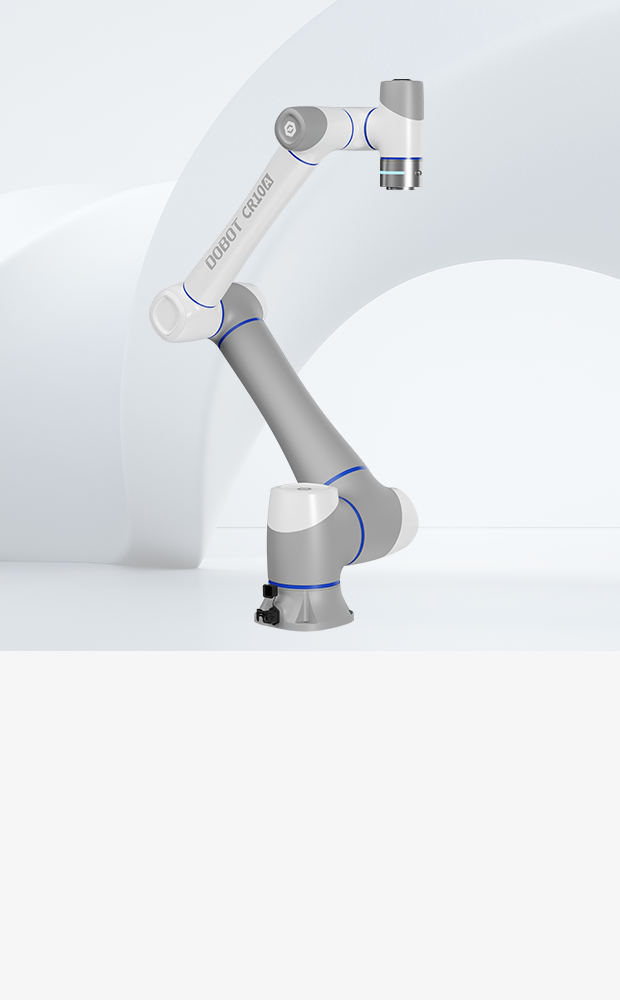

DOBOT robot CRAF series CR10AF

plus VAT, plus shipping costs

The next generation of force-controlled cobots

Designed for high-end manufacturing applications such as precision assembly, complex grinding, and medical automation, the DOBOT CRAF series redefines intelligent force control with its proprietary algorithms and integrated high-resolution sensors.

It offers plug-and-play usability without installation or deployment, enabling adaptive force applications and seamless human-robot collaboration—setting a new standard for precision, safety, and ease of use in smart manufacturing.

Maximum payload: 10 kg

Working radius: 1,300 mm

Repeatability: ±0.03 mm

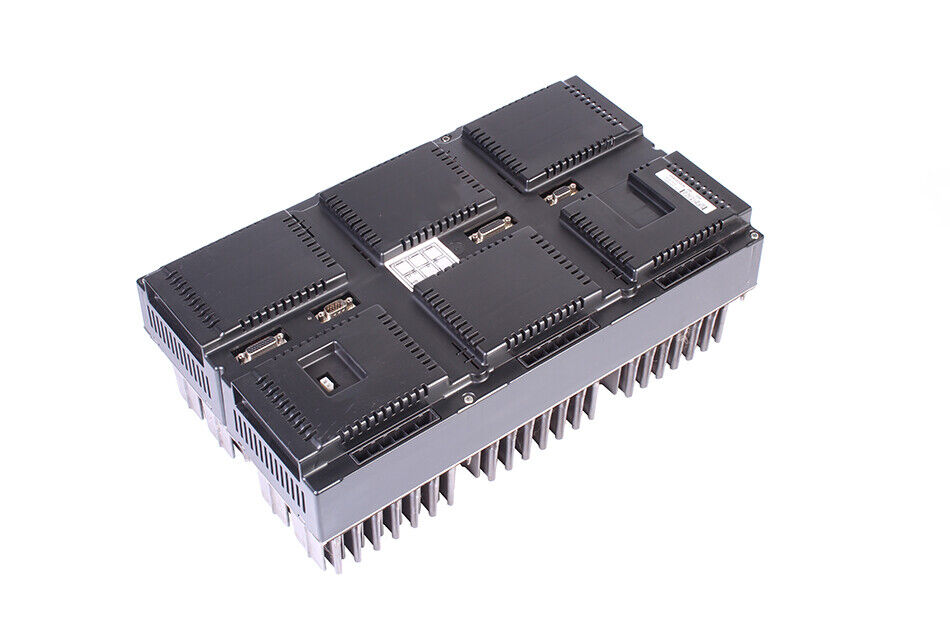

All-in-one power control, plug-and-play

The CRAF series is based on the CRA series and features a high-precision 6-axis force sensor integrated at the flange end, enabling the cobot to achieve improved compliant force control and precise operating functions.

Flange with ring status light

Features a ring-shaped status light for real-time visibility of the robot's status. Equipped with a push-to-pull button.

Unused end interface

Does not occupy any tool-side RS485 or I/O ports, ensuring compatibility with external devices (such as electric grippers or the VX500 Smart Camera).

Intelligent force control with safety and reliability

Gentle pulling – easy to control

The entire flange serves as an active resistance zone for intuitive teaching.

Assembly

Users can constrain the alignment for precise path programming.

welding

Thanks to its extremely low starting force (<2 N), the CRAF robot can be effortlessly controlled by simply touching a straw. This enables millimeter-precise dragging training and achieves a point-to-point accuracy of 0.1 mm.

polishing

The CRAF robot maintains constant force with automatic compensation, ensuring flawless performance in high-precision applications such as car sanding and polishing.

healthcare

The robot features real-time environmental detection (e.g., detection of table height differences) with automatic surface scanning, enabling adaptive motion control for precise task execution based on environmental feedback.

Other collaborative scenarios

With integrated force-sensitive collision detection (sensitivity up to 1 N), the CRAF robot significantly reduces collision forces while achieving an industry-leading shock resistance of 2000 N – reliably handling frequent operational shocks and collisions caused by disturbances in real-world applications.

Application scenarios

· welding

Loading and unloading

Stick

Transport

Standard Shipping

Estimated shipping time: 1-2 days for spare parts

Do you need more than what's shown in the shop, or a similar product? Or are you unsure if it's the right one for you? Feel free to submit a product inquiry.